EN19

Grade Introduction:

EN19 Steel is a high-quality engineering alloy steel containing chromium and molybdenum. It falls in a class of low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsion strength. It can be heat treated in a number of ways to give it a combination of properties.

EN19 Steel is one steel grade in BS 970-1955 standard, which is the specification for wrought steels for mechanical and allied engineering purposes. Although there is a new version of BS 970-1996 latest edition. And EN19 steel grade is similar to the 709M40 grade in the new version. EN19 Alloy Forging Steel.

Grade Application

EN19 Alloy steel was originally introduced for use in the machine tool and motor industries for gears, pinions, shafts, spindles, and the like. Later its applications became much more extended and it is now widely used in areas such as the oil and gas industries. EN19 is suitable for applications such as gears, bolts, studs, and a wide variety of applications where a good quality high tensile steel grade is suited.

Equivalent Grades

Internal Standard |

BS |

Din |

IS |

Sae/Aisi |

EN19 |

709M40 |

42CrMo2 |

40Cr4Mo3 |

4140 |

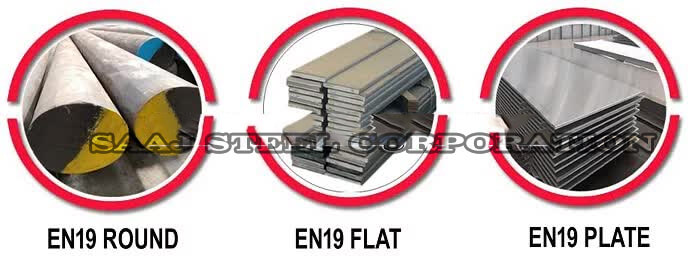

Our Supply Range

We supply to automotive ancillaries and OEM customers. The products we manufacture are used as input for manufacturing of automotive and general engineering components. These components are further assembled into systems fitted in automobiles and other engineering applications.

| Product Type | Size Range |

|---|---|

| Forged Round Bars | 140mm Dia and above |

| Rolled Round Bars | 12mm Dia and above |

| Forged Flat Bars | Thickness: 32mm to 510mm, Width: 65mm to 1050mm |

| Rolled Flat Bars | Thickness: 6mm to 110mm, Width: 25mm to 810mm |

Chemical Composition

The following table shows the chemical composition of En19 steel:

Element |

C |

Si |

Mn |

P |

S |

Cr |

Mo |

Fe |

Content (%) |

0.35-0.45 |

0.15-0.30 |

0.50 – 0.80 |

0.035 |

0.040 |

0.90-1.50 |

0.20-0.40 |

96.78-97.77 |

Heat Treatment

Steel is heated at 845°C followed by quenching in oil. Before hardening, it can be normalized by heating at 913°C for a long period of time followed by air cooling.

Hardness

Properties |

Metric |

Imperial |

Hardness, Brinell |

197 |

197 |

Hardening

En19 alloy steel can be hardened by cold working or heating and quenching.

Thermal Properties

Average Coefficient of Linear Thermal Expansion (μm/m.K) |

||||

Temp. Range °C |

20-100 |

20-200 |

20-400 |

20-600 |

Coefficient |

12.2 |

12.6 |

13.7 |

14.6 |

Electrical Resistivity ( μΩ.m) and Thermal Conductivity (W/m.K) |

||||

Temp. Range °C |

100 |

200 |

400 |

600 |

Electrical Resistivity |

0.263 |

0.326 |

0.4575 |

0.646 |

Thermal Conductivity |

42.6 |

42.2 |

37.7 |

33.0 |

Forging Properties

En19 steel is forged at 926 to 1205°C.

Stress Relieving

Annealed: 600-650°c Heat in needed.

Hardened: 500-550°c Heat in needed.

Welding

EN19 steel can be welded using all conventional techniques. However, the mechanical properties of this steel will be affected if it is welded in the heat-treated condition, and post weld heat treatment should be performed.

Machinability

EN19 alloy steel has good machinability in the annealed condition.

Mechanical Properties

Properties |

Metric |

Imperial |

Tensile strength |

655 MPa |

95000 psi |

Yield strength |

415 MPa |

60200 psi |

Bulk modulus (typical for steel) |

140 GPa |

20300 ksi |

Shear modulus (typical for steel) |

80 GPa |

11600 ksi |

Elastic modulus |

190-210 GPa |

27557-30458 ksi |

Poisson’s ratio |

0.27-0.30 |

0.27-0.30 |

Elongation at break (in 50 mm) |

25.70% |

25.70% |

Hardness, Brinell |

197 |

197 |

Hardness, Knoop (converted from Brinell hardness) |

219 |

219 |

Hardness, Rockwell B (converted from Brinell hardness) |

92 |

92 |

Hardness, Rockwell C (converted from Brinell hardness. Value below normal HRC range, for comparison purposes only) |

13 |

13 |

Hardness, Vickers (converted from Brinell hardness) |

207 |

207 |

Machinability (based on AISI 1212 as 100 machinability) |

65 |

65 |

Physical Properties

DENSITY (G/CM 3) |

8.08 |

DENSITY (LB/IN 3) |

0.292 |

MELTING POINT (°C) |

1425 |

MELTING POINT (°F) |

2600 |

Tempering

En19 alloy steel can be tempered at 205 to 649°C depending upon the desired hardness level. The hardness of the steel can be increased if it has a lower tempering temperature. For example, a tensile strength of 225 ksi can be achieved by tempering at 316°C (600°F), and tensile strength of 130 ksi can be achieved by tempering at 538°C(1000°F).

Normalizing

Heat 870°C – 900°C and cool in still air.

Annealing

EN19 steel is annealed at 872°C followed by slowly cooling in the furnace.

Density

The density of EN19 Alloy steel material: 7.85kg/cm3

Supply Cities

Ambattur, Bangalore, Chennai, Chengalpattu, Coimbatore, Dindigul, Guindy, Madurai, Nellore, Hyderabad, Hosur, Tiruvallur, Tirupur, Tuticorin, Andhra Pradesh, Karnataka, Puducherry, Kerala, Kanyakumari, Telangana, Salem, Thanjavur, Trichy, Erode, Vellore, Karur, Nagercoil, Kanchipuram, Karaikudi, Pudukottai, Nagapattinam, Nemili Thiruvanmiyur, Perungudi, Kurichi, Kakkalur, Keelanagachi, Paramakudi, Thandarai, Alathur, Kodur, Mallur, Gangaikondan, Sriperumbudur, Oragadam,Irungattukottai, Vallam Vadagal, Siruseri,Eraiyur, Manapparai, Perundurai, Ranipet, Gummidipoondi, Cheyyar, Manamadurai, Tindivanam , Mappedu , Thervoykandigai , Nilakottai, Shoolagiri, Kurubarapalli, Bargur, Thirumudivakkam, Cuddalore, Pillaipakkam.

People also search as

EN19 Steel Round Bar, EN19 Steel Round Bar Manufacturers, EN19 Steel Suppliers, EN19 Stockist, EN19 Steel Dealers, EN19 Steel Distributors, EN19 Wholesalers, EN19 Steel Traders, EN19 Steel Square Distributors, EN19 Steel Flat Bar, EN19 Steel Companies Near me.

EN19, EN19 Steel, EN19 Chemical composition, EN19 Mechanical properties, EN19 Equivalent Grades, EN19 Steel plate, EN19 Steel sheet, EN19 Manufacturers, EN19 Suppliers, EN19 Dealers, EN19 Stockist, EN19 Distributors, EN19 Wholesalers, EN19 Traders.

Addition to other grades

MS, EN1A, EN3B, EN8, EN8D, EN9, EN19, EN24, EN31, EN32B, EN36C, EN41B, EN43B, EN47, EN353, IS2062, 42Crmo4, HCHCR, D2, D3, H-11, H-13, CW-1, OHNS, M2, M35, M42, DIN1.2714, P20, P20+S, P20+Ni, SCM420, ASTMSA-36, ASTMSA-105, SAE1018, SAE4140, SAE8620, 16MNCR5, 20MNCR5, C20, C45, C50, C60, CK45, 20C8, 40C8, 45C8, 55C8, C55MN75, SAE52100, S40C, S355J2G3.